|

text by Vicki Sign up here to join our weekly email newsletter!

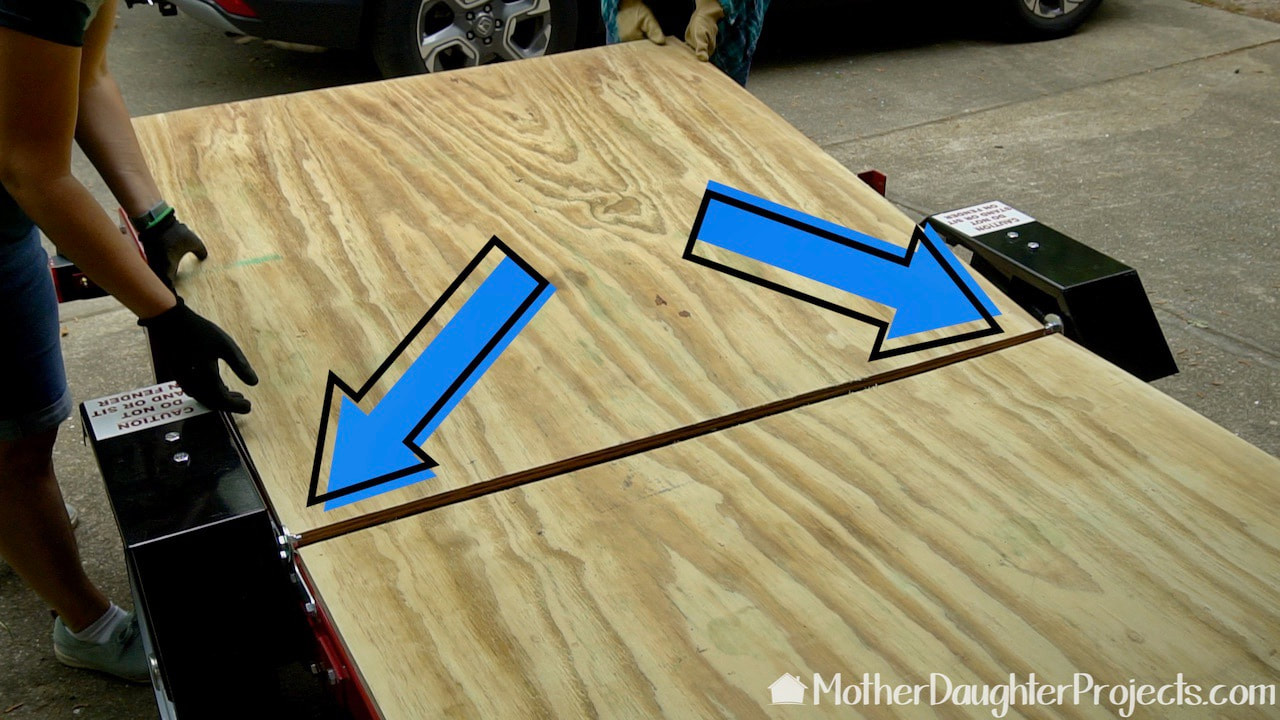

We are continuing the series about assembly of a Harbor Freight DIY Utility Trailer. With the framing and wiring completed, it's time to add the plywood decking.

The addition of the plywood decking signaled that the work on the trailer was almost complete. But, there were still a few more things to do and ultimately we decided we needed a couple of tweaks to some of the previous work. Along the way, we discovered and purchased a couple of really useful tools! Trailer Essentials:

Materials/Tools:

The decking consists of one sheet of plywood cut in half. The first issue we had to deal with were these bolt heads on each corner of the frame. Since they stuck up above the frame, we needed to drill into the backside of the plywood to create a recessed area for these bolt heads to fit into in order for the plywood to lay flat.

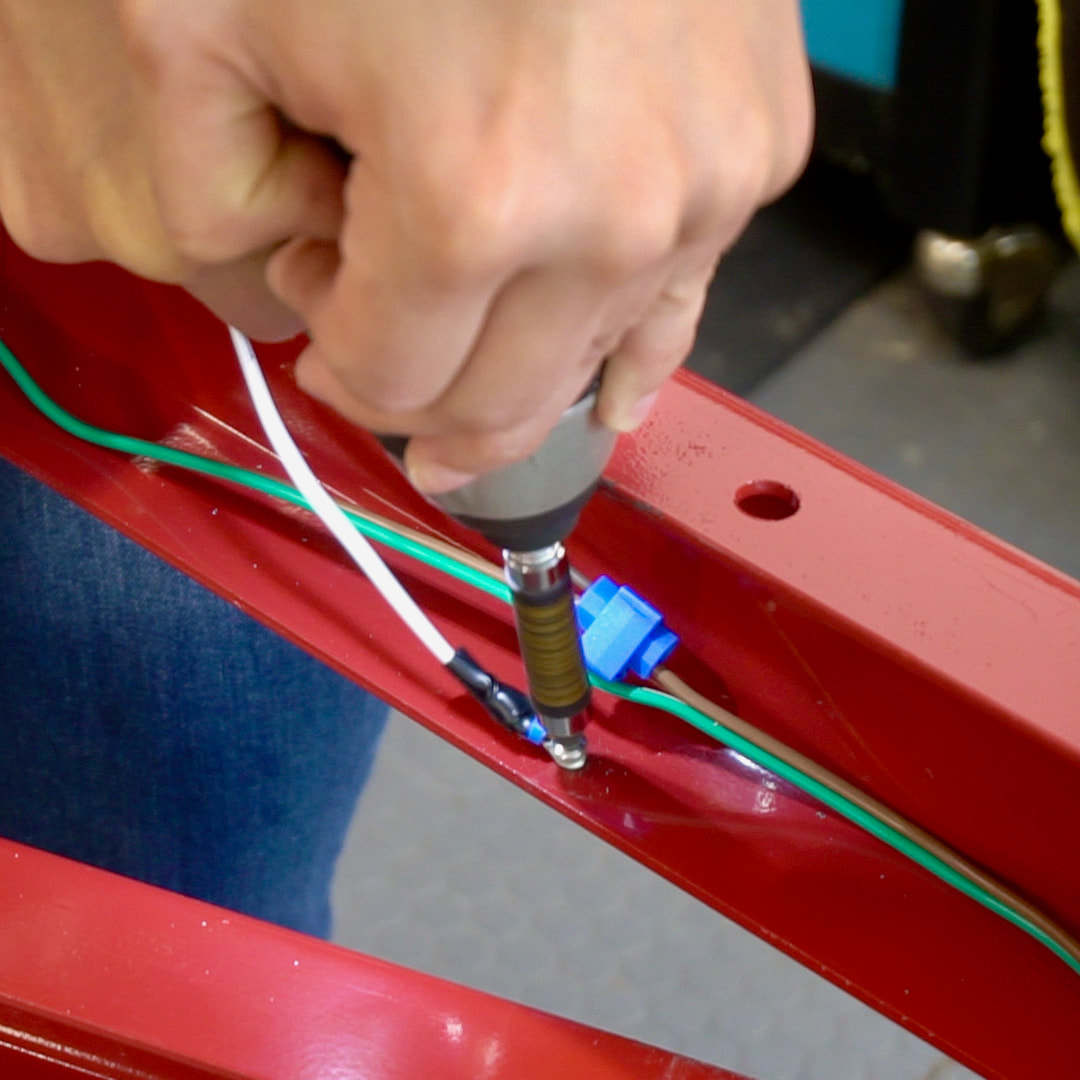

This was one of the tweaks we ultimately made to the decking. After living with the decking for a few weeks, Steph decided the bolt heads on the topside needed to be recessed. So she took the decking off and used a Forstner bit to drill holes to recess the bolt heads. This Rockler drill press accessory insured they were all the same depth and perfectly straight.

There are two more videos in this Harbor Freight Utility trailer build series. In the next two, we'll show how the trailer folds for storage, as well as how to hook up the trailer to the car for towing.

What do you think, should we add additional rails to the other three sides? Please note: This is not a sponsored post. FYI: We are not professionals, and we don't claim to be. This is what we found worked for our project. Yours may need a little different approach. Safety first! FYI: Affiliate links are being used on this page. Purchasing via these links help support MDP! Related Projects

2 Comments

Tom Hogan

8/18/2021 07:34:03 am

Two things that I learned putting the deck on my Harbor Freight trailer:

Reply

Bart Tizio

10/24/2023 11:10:31 pm

At minimum the recessed bolt heads should be covered over with a product like PC woody. If not holes will capture water and compromise the wood over time.

Reply

Leave a Reply. |