|

text by Vicki Sign up here to join our weekly email newsletter!

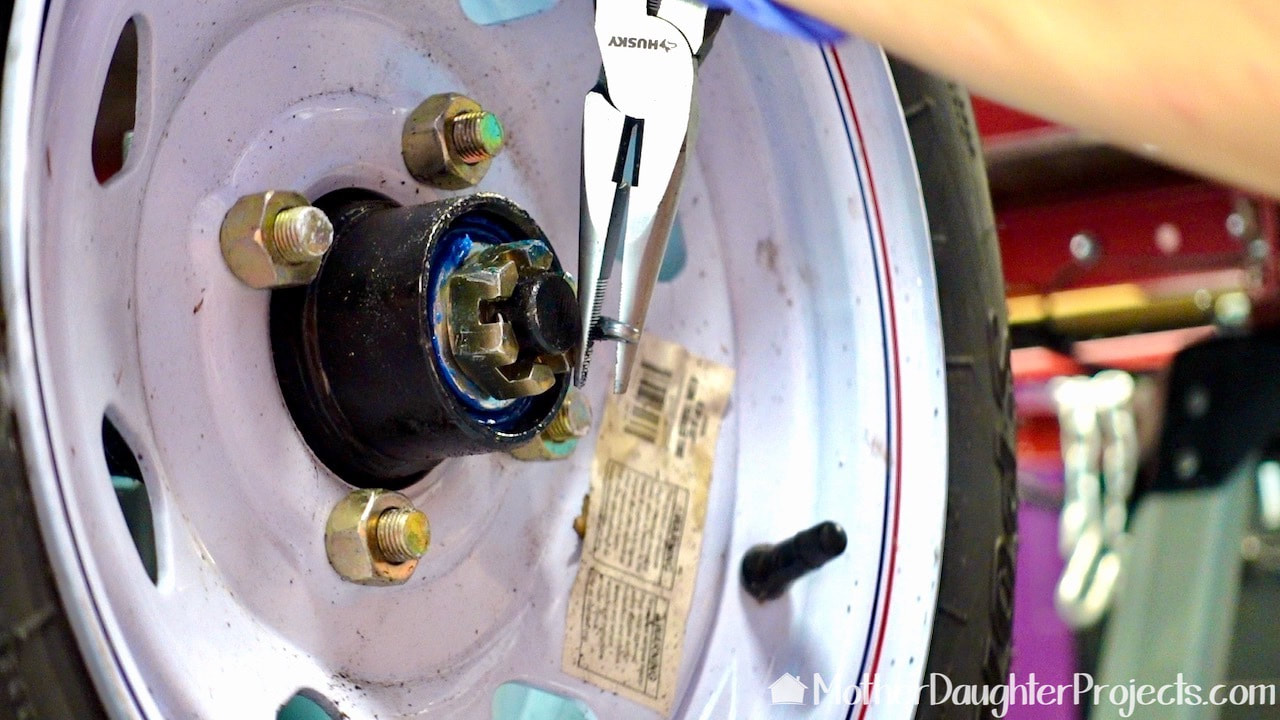

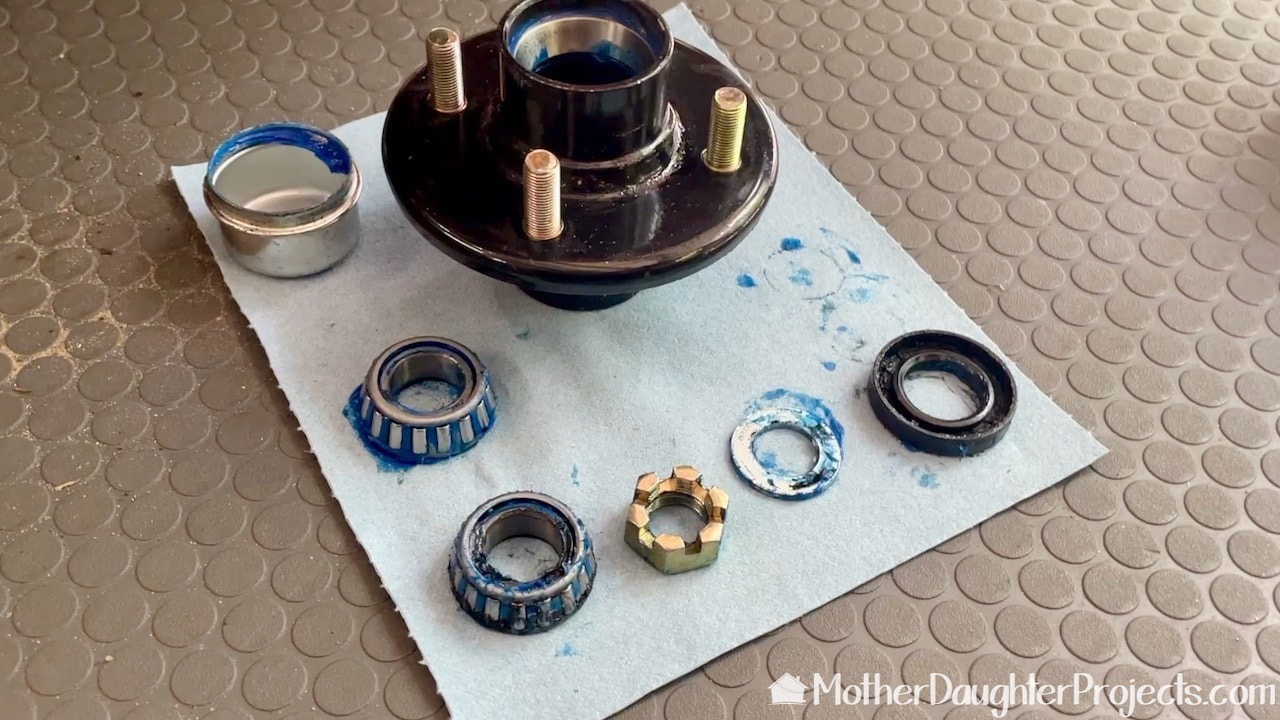

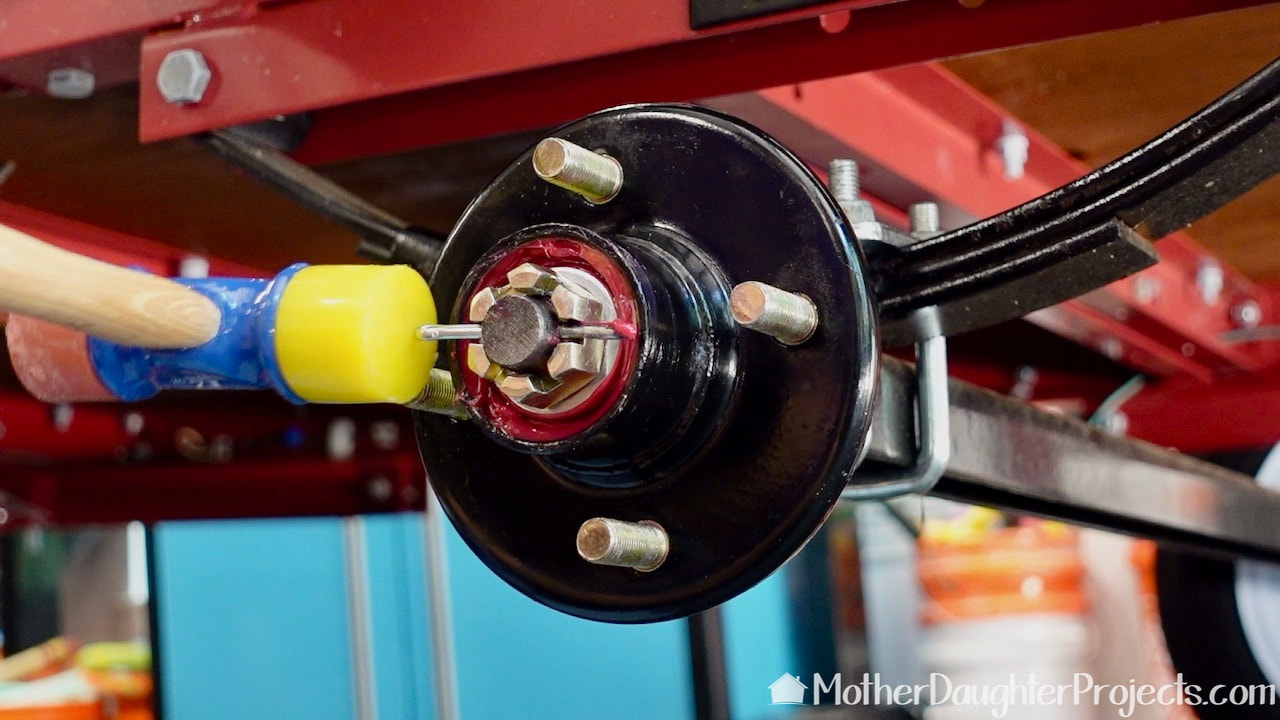

She said she was going to do it and she did it...repack the bearings on the trailer!

I (Vicki) had no clue as to what was involved in this process which made it fascinating to watch! After watching her and seeing the video, I think I could actually repack bearings as well. My dad was an auto mechanic all of his life. As many of you know, he passed away in May, 2020. Both Steph and I, during the trailer maintenance process, commented on just how proud he would be of his granddaughter! That thought makes me happy...

Once Steph removed all the parts, it was obvious that the bearings did not need repacking, but she wanted to go through the process anyway. It was a real learning experience. Once she learned from doing the first wheel, the second was a breeze!

Please note: This is not a sponsored post. FYI: We are not professionals, and we don't claim to be. This is what we found worked for our project. Yours may need a little different approach. Safety first! FYI: Affiliate links are being used on this page. Purchasing via these links help support MDP Related Projects

0 Comments

Leave a Reply. |